What is a SCARA robot?

A SCARA robot means Selective Compliance Assembly Robot Arm. SCARA robots have a special arm design. This design helps them move quickly and accurately from side to side. Many industries use SCARA robots. Electronics and car companies use them for assembly and packaging jobs. The Asia-Pacific area uses SCARA robots the most.

SCARA Robot Basics

What is a SCARA Robot

A SCARA robot is a kind of industrial robot. It is made for jobs that need to be fast and very exact. ISO 8373 says a SCARA robot has two rotary joints. These joints are side by side and let it move in one flat area. This design lets the robot bend sideways but stay stiff up and down. SCARA robots are great for pick-and-place, assembly, and packaging. They can move things quickly and with care. That is why electronics and car factories use them a lot.

SCARA Acronym and History

SCARA stands for “Selective Compliance Arm for Robotic Assembly.” People started using this name in the late 1970s. In 1979, Sankyo and IBM made the first SCARA robots. These robots were made at Yamanashi University in Japan. This was a big change for scara robots in factories. Factories soon used scara robots to handle wafers in making semiconductors. This set a new rule for being fast and exact.

Design and Movement

SCARA robots have a special arm shape. The arm has two main joints that spin around up-and-down lines. This gives the robot a round work space. The design lets the robot move fast and with care in a flat area. The up-and-down part stays stiff for good vertical moves. This special bending lets scara robots work smoothly and quickly. The table below shows how scara robots are different from other robots:

|

Feature/Aspect

|

SCARA Robots

|

Cartesian Robots

|

Articulated Robots

|

|---|---|---|---|

|

Joint Configuration

|

Rotating shoulder and elbow joints

|

Linear actuators (X, Y, Z)

|

Multiple rotary joints

|

|

Movement Axes

|

X, Y, Z, plus rotation

|

Linear in X, Y, Z

|

Complex 3D movements

|

|

Rigidity

|

Rigid vertically, flexible horizontally

|

High rigidity

|

Flexible, less rigid

|

|

Work Envelope

|

Circular

|

Rectangular

|

Large, complex

|

|

Speed and Precision

|

Fast, high precision

|

High precision

|

Good for complex tasks

|

SCARA robots use four servo axes to help them move together. This helps them do the same job over and over with care. They are small and fast, so they fit in tight spaces and busy assembly lines.

SCARA Robots in Industry

Applications of SCARA Robots

SCARA robots are important in many industries. They are fast and very accurate. These robots do jobs that need to be done the same way every time. Here are some main ways they are used:

-

Pick and place: SCARA robots move small parts fast and with care. They help put together electronics.

-

Machine tending: They put parts into machines and take them out. This makes work faster.

-

Packaging: These robots put things into boxes or containers quickly.

-

Inspection: SCARA robots check if products are good using cameras and sensors.

Other industries use SCARA robots for special jobs too:

|

Industrial Application

|

Typical Tasks Performed

|

|---|---|

|

Micro-automation in pharmaceuticals

|

Moving tiny parts in drug making and research; handling pieces smaller than 1mm

|

|

Food and beverage industry

|

Processing and packing food; using safe materials and easy cleaning

|

|

3D printing assistance

|

Helping with 3D printing; putting out materials; finishing work

|

|

Laboratory automation

|

Getting samples ready, keeping things clean, and working with lab computers

|

|

Retail automation

|

Handling items in vending machines or small warehouses; using object recognition

|

SCARA robots also help in making batteries, moving goods, life sciences, and machines. For example, a factory made its sensor line better by using a SCARA robot with a gantry robot. This made more products and saved space. It shows how SCARA robots help make work areas flexible.

Benefits of SCARA Robots

SCARA robots have many good points over other robot arms. Their shape lets them move fast and be very exact, mostly for side-to-side jobs. Here are some main benefits:

-

SCARA robots are great for fast, repeated jobs with high accuracy.

-

Their arm design makes them finish tasks quicker, so they are good for pick-and-place.

-

They stay quick even when lifting heavier things, unlike some other robots.

-

SCARA robots are small, so they save space and cost less to set up.

-

They have motors and controllers inside, so they are easy to install and need less wiring.

-

They are simple to program and connect, often with plug-and-play.

-

SCARA robots need less fixing because they have fewer moving parts, which saves money.

-

Their high accuracy helps control quality and cut down on waste.

SCARA robots help companies spend less by needing fewer workers and making work faster. They also make jobs safer by doing dangerous work.

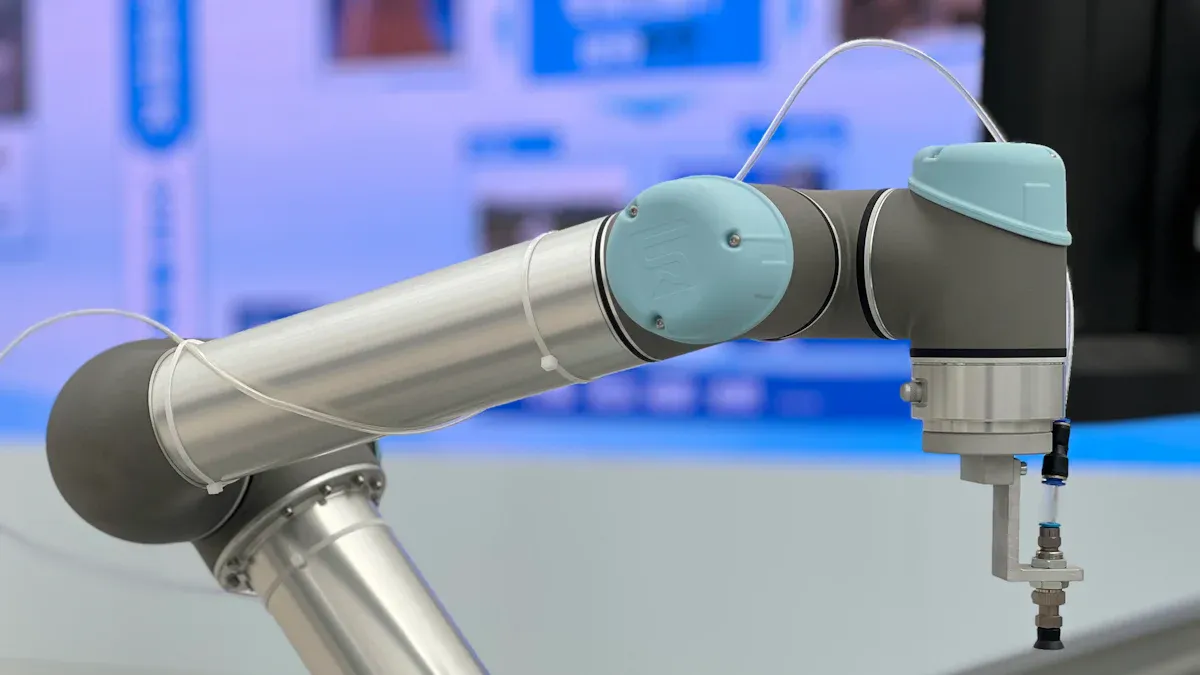

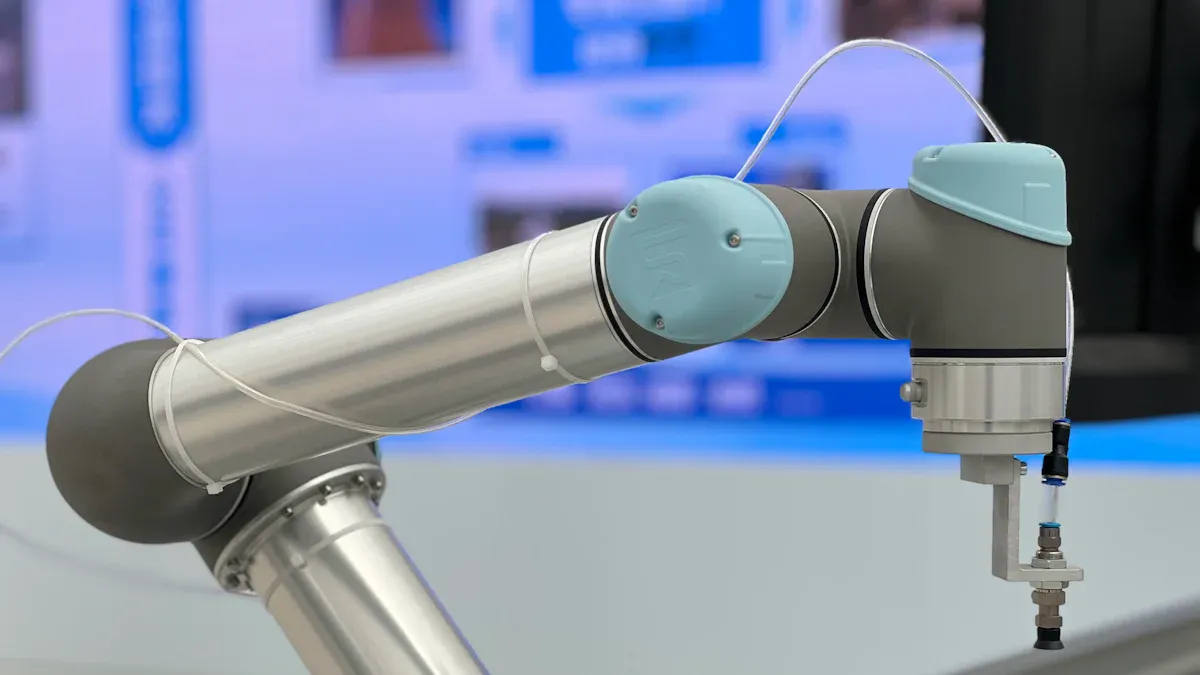

In real life, companies that make electronics and cars have seen big improvements. For example, the EVS3-400 SCARA robot helps pack and move fragile electronic parts. This makes work more accurate and faster.

Limitations of SCARA Robots

SCARA robots are strong but have some weak points:

-

SCARA robots are small and do not reach far, so their work area is limited.

-

They cannot lift very heavy things. For example, if a robot lifts 6 lbs, it should be able to hold about 10-12 lbs.

-

They mostly move sideways and cannot go up and down much.

-

SCARA robots are not good for lifting heavy things or working in big spaces.

-

They are not as flexible as 6-axis robots, so they cannot do very hard or big jobs.

SCARA robots are best for fast, careful jobs with small parts in tight spaces. They are not the best for jobs that need lots of movement or heavy lifting.

Choosing a SCARA Robot

Picking the right SCARA robot means thinking about some key things. Here are some tips:

-

Payload and reach: Make sure the robot can hold the parts and tools you need.

-

Precision and accuracy: Pick a robot that is exact enough for your job, like in electronics or medicine.

-

Speed and cycle time: Think about how fast the robot must work to meet your goals.

-

Cost-effectiveness: Choose a robot that fits your budget and needs.

-

Ease of integration and programming: Find robots that are easy to set up and use.

|

Factor

|

Explanation

|

|---|---|

|

Payload

|

The robot must hold the part and tool together. The right payload saves space and money.

|

|

Speed

|

SCARA robots are some of the fastest, which is good for quick work.

|

|

Footprint

|

SCARA robots are usually smaller than other robots with the same reach.

|

|

Repeatability

|

High accuracy in X-Y is needed for jobs like electronics.

|

|

Articulation

|

SCARA robots have 4 axes, good for pick and place, assembly, and putting out materials.

|

|

Work Envelope

|

The robot’s reach must cover all spots in the work area.

|

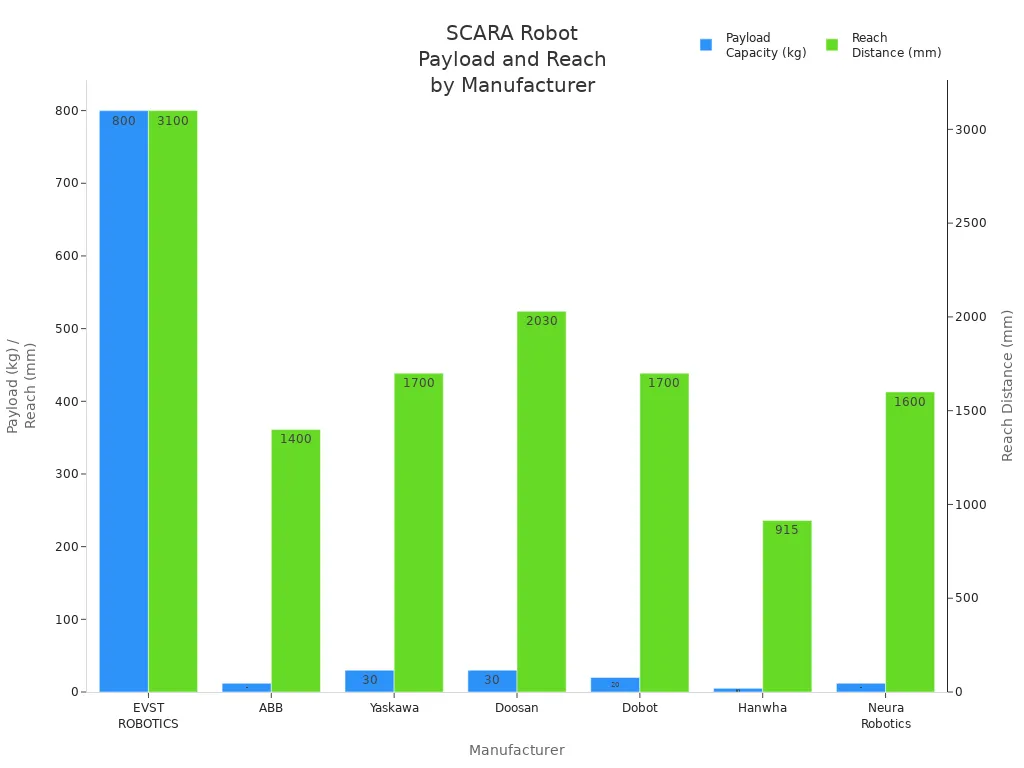

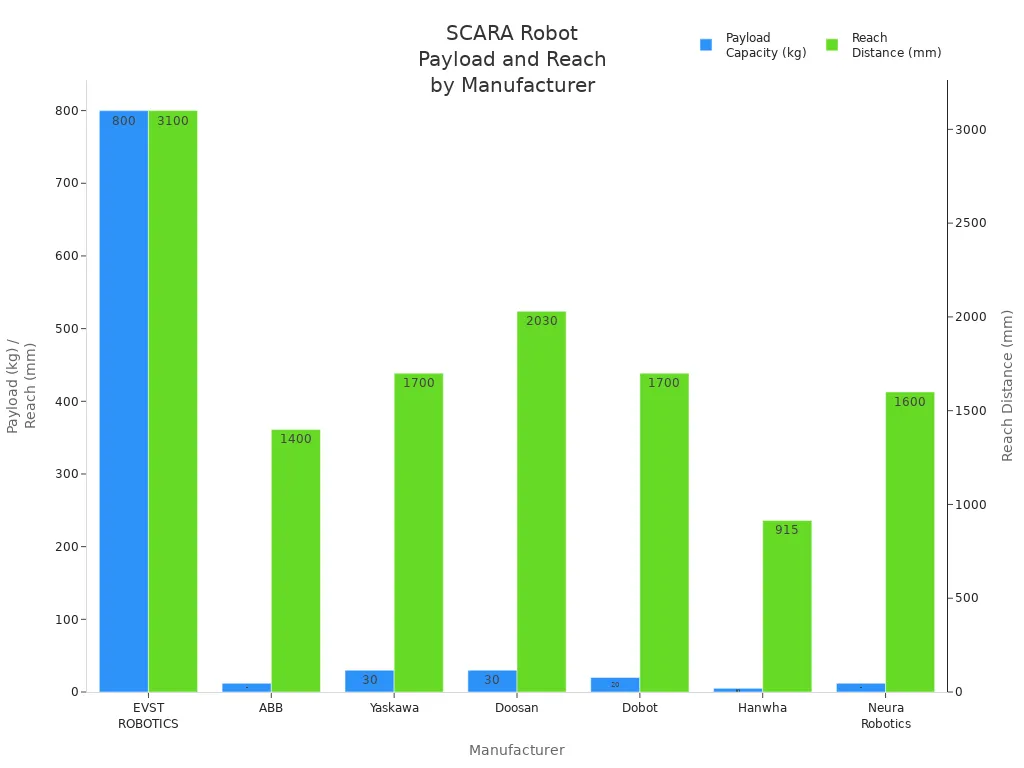

When looking at brands, EVST ROBOTICS is known for its wide range of payloads (3–800 kg) and long reach (up to 3100 mm). EVST is as good as top brands in accuracy and speed, with repeatability as fine as ±0.025 mm and speeds up to 2 m/s. EVST also lets you use custom programs and smart vision systems, so it works for many jobs.

Cost and Trends

The price of SCARA robots changes based on what they can do, how much they can lift, and how far they reach:

|

Model Tier

|

Typical Price Range

|

Payload & Reach Characteristics

|

Features & Examples

|

|---|---|---|---|

|

Entry-level

|

$10,000 – $40,000

|

Simple jobs, not much weight or reach

|

Easy assembly or moving things; examples: FANUC SR-20iA, ABB IRB 920, Epson basic SCARA

|

|

Mid-range

|

$40,000 – $60,000

|

Can lift more, do harder jobs

|

More exact, faster, more flexible; mid-level FANUC models

|

|

High-end

|

$60,000+

|

Smart control, better sensors

|

Used in very exact jobs; has vision systems and smart sensors

|

|

Used Robots

|

30-50% less than new

|

Depends on condition and warranty

|

Cheaper but may not have new tech or warranty

|

Most companies get their money back from SCARA robots in 6 to 18 months. After that, they keep saving money and making more products for years.

SCARA robots are getting smarter and easier to use. New trends include:

-

AI for harder jobs and better vision.

-

Machine learning for robots to make choices on their own.

-

Better vision systems to see parts and plan moves.

-

Modular designs to change setups easily.

-

Better safety for people working with robots.

-

Open-source robotics for easier programming and setup.

Experts think SCARA robots will keep growing fast. The market could go from about $10 billion in 2024 to over $16 billion by 2030. This is because more companies want automation, new tech is coming, and more jobs need robots.

SCARA robots are fast and very accurate. They can also do many different jobs. This helps companies work better and make fewer mistakes. Picking the right SCARA robot is important for good results.