What Are Laser Welded Pillow Plate Heat Exchangers

Laser welded pillow plate heat exchangers have two metal sheets. These sheets are joined together by laser welding. This makes a shape that looks like a pillow. The process makes strong and good channels for heat to move. The pillow plate design works with advanced systems. One example is the EVS Robotics Laser Welding System for Pillow Plates. This helps the heat exchanger work very well. More people around the world want better heat exchangers. This makes the market grow fast. New materials and technology make them last longer. They also help heat move better.

Key Takeaways

-

Laser welded pillow plate heat exchangers have two metal sheets. These sheets are joined by laser welding. The welding makes strong, wavy channels. These channels help heat move better. They also help fluids flow more easily.

-

Advanced systems like EVS Robotics help with welding. They make sure the welding is always correct. This makes the heat exchangers last longer. It also makes them work better. They can handle high pressure and heat.

-

These exchangers can be used in many ways. They are simple to clean. This makes them great for food, chemical, and energy industries. These places need good and steady heat transfer.

Construction and Laser Welding Techniques

Pillow Plate Structure

Pillow plate heat exchangers have two metal sheets joined together. After welding, the sheets are filled with water or air. This makes wavy channels inside the plate. The channels look like pillows, which is why they have this name. These channels make more space for heat to move. They also help fluids move in a fast, swirling way. This helps the heat exchanger work better.

-

Two metal plates are welded at the edges and in patterns.

-

Filling the plates makes pillow-shaped, wavy channels.

-

Spot welds guide how fluids move and create swirling flows.

-

The wavy shape keeps dirt from building up and helps heat move.

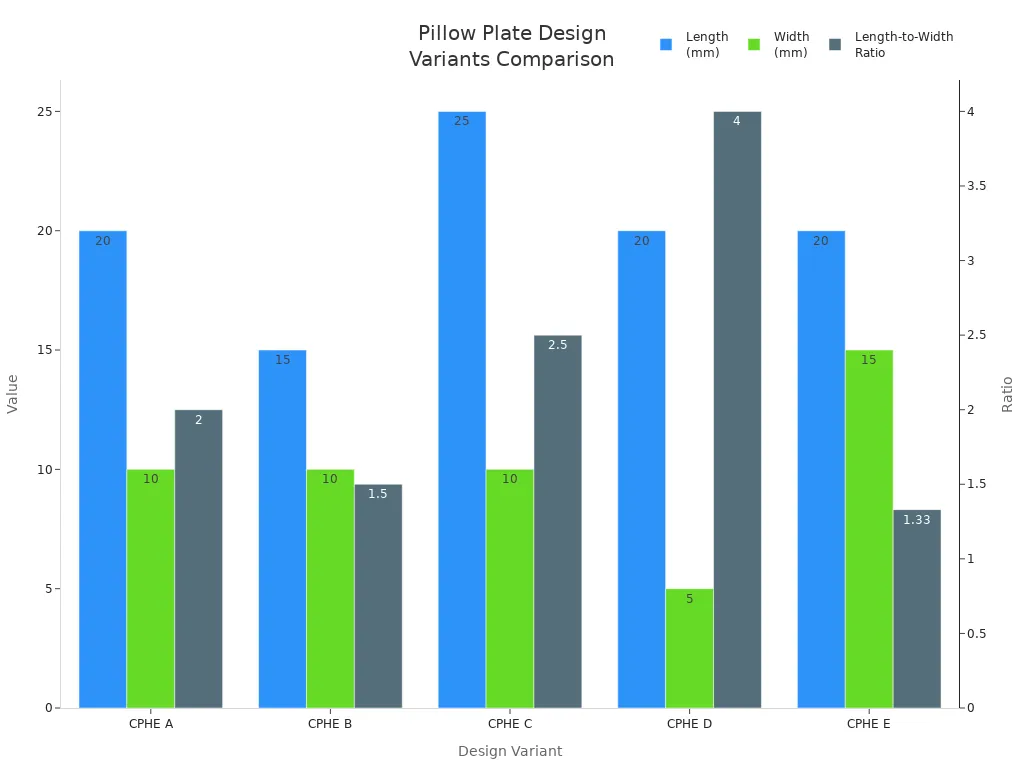

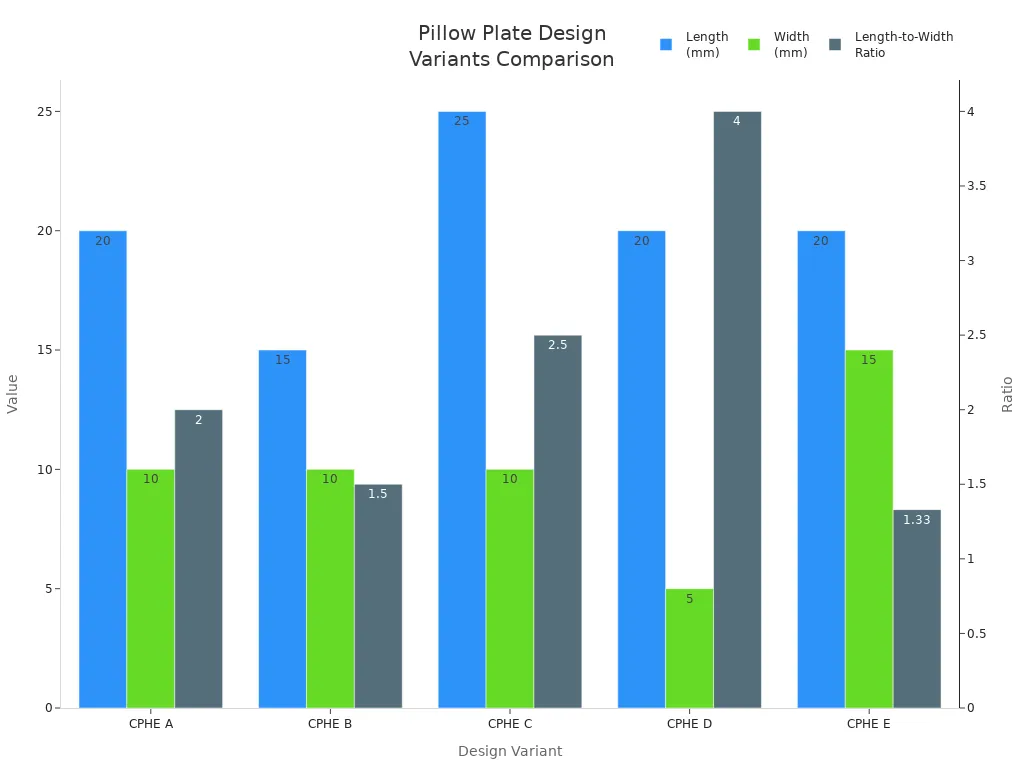

Pillow plate structures can be many shapes and sizes. The design changes to fit what each job needs. The table below shows some common types:

|

Design Variant

|

Length (l) mm

|

Width (d) mm

|

Length-to-Width Ratio (l/d)

|

|---|---|---|---|

|

CPHE A

|

20

|

10

|

2

|

|

CPHE B

|

15

|

10

|

1.5

|

|

CPHE C

|

25

|

10

|

2.5

|

|

CPHE D

|

20

|

5

|

4

|

|

CPHE E

|

20

|

15

|

1.33

|

This makes it easy for engineers to use pillow plate heat exchangers in many ways.

Note: The pillow plate design gives more space for heat to move and makes fluids swirl, so it works better than flat plate or shell-and-tube designs.

Laser Welding Process

Laser welding is very important for making pillow plates. It uses strong lasers to join two metal sheets very carefully. In factories, machines like the EVS Robotics Laser Welding System for Pillow Plates do this job. The machine holds the sheets tight so they do not move. It then uses a drag-type welding structure to make smooth seams.

The main steps in laser welding for pillow plates are:

-

Hold the two metal sheets together with special clamps.

-

Use a laser to weld the sheets in a pattern, row by row.

-

Fill the welded sheets with water or air to make the pillow shape.

-

Seal the edges with a final weld to keep air from leaking.

The EVS Robotics system is special because it is very accurate (0.08mm per 1000mm) and does the same thing every time (0.05mm). It uses a shielding gas plate to protect the weld and keep it shiny. The SIEMENS CNC controller makes sure every weld is just right. This means each pillow plate can handle high pressure and heat.

|

Feature/Aspect

|

Description/Specification

|

|---|---|

|

Welding Structure

|

Drag-type welding structure for smooth seams without rough edges

|

|

Clamping Mechanism

|

Special clamps to keep the sheets in place

|

|

Positioning Accuracy

|

0.08mm per 1000mm

|

|

Repeatability

|

0.05mm

|

|

Laser Power Options

|

Fiber or CO₂ lasers at 3000W or 4000W

|

|

CNC Controller

|

SIEMENS CNC controller

|

|

Weld Seam Quality

|

Clean seams with no rough edges, no extra work needed

|

Tip: Using machines for laser welding helps avoid mistakes and makes sure every pillow plate is made well.

Material Options

Different materials are used for laser welded pillow plate heat exchangers. Stainless steel is the most common because it does not rust and can handle high pressure and heat. Some pillow plates use copper or aluminum for special jobs. Copper moves heat well and is good for small spaces. Aluminum is light and works well when weight matters.

|

Material

|

Impact on Performance and Customization

|

|---|---|

|

Stainless Steel

|

Does not rust, clean, handles high pressure (up to 60 bar), high heat (up to 800°C)

|

|

Copper

|

Small, moves heat well, good for tough jobs

|

|

Aluminum

|

Light, moves heat well, small size

|

Pillow plate heat exchangers can be changed in many ways:

-

Many shapes and sizes to fit tanks or special machines.

-

One or two sides for heating or cooling.

-

Change channel sizes and weld patterns to work better.

-

Can be used as plates inside tanks, plate banks, or tank jackets.

These choices make laser welded pillow plate heat exchangers useful for many jobs, like food factories, chemical plants, and energy systems.

Advantages and Applications of Pillow Plate Heat Exchangers

Efficiency and Durability

Laser welded pillow plate heat exchangers work better than old types. Laser welding makes the welds strong and very exact. This keeps the plates flat and smooth. The process does not hurt the metal much. The pillow plate shape makes the liquid inside swirl more. This helps heat move faster between the plates. Tests show these exchangers can be up to 37% more efficient. They are built strong, so they can handle high heat and pressure. The smooth plates do not get dirty easily, so cleaning is simple. If you check and clean them gently, they last a long time.

Industrial Applications

Many factories use pillow plate heat exchangers because they are strong and flexible. The dairy industry uses them to cool milk fast after pasteurizing. Food and drink companies use them to chill soda, wine, and beer. Chemical and drug factories use them to heat and cool liquids safely. Other uses are in ice machines, heat pumps, and tank jackets. The EVS Robotics system is trusted by many companies for these jobs.

|

Industry

|

Primary Applications

|

|---|---|

|

Dairy

|

Cooling milk after pasteurization

|

|

Food & Beverage

|

Chilling drinks like soda, wine, and beer

|

|

Chemical & Pharmaceutical

|

Heating and cooling solutions

|

|

Other Industrial Uses

|

Ice machines, heat pumps, tank jackets

|

Recent Innovations

New ideas make pillow plate heat exchangers smaller, lighter, and better. Some new shapes, like dimples and ellipsoids, help fluids move faster. Factories now use smart controls to watch and change how the exchangers work. Makers use copper and aluminum, which move heat faster than stainless steel. Using fiber lasers saves energy and makes building more exact. These changes mean pillow plate exchangers will help save energy and protect the planet in the future.

Laser welded pillow plate heat exchangers have two metal sheets. These sheets make strong channels for heat to move. Advanced systems, like EVS Robotics, weld the sheets very carefully. They can also make many different designs. These heat exchangers work well and are easy to clean. They are used in food, chemical, and energy factories.

-

Small size and can be changed to fit needs

-

Works with high pressure and heat

-

Simple to keep clean and fix

These exchangers are a good pick for people who want strong and efficient ways to move heat.

FAQ

What makes laser welded pillow plate heat exchangers different from regular heat exchangers?

Laser welded pillow plate heat exchangers have two metal sheets. The sheets have special channels inside them. These channels let fluids move quickly. This helps heat move from one place to another better.

Can pillow plate heat exchangers handle high pressure and temperature?

Yes, they can. These exchangers use strong welds and tough metals. They work well when there is a lot of pressure or heat.

Where do companies use pillow plate heat exchangers the most?

Many companies use them in food factories and chemical plants. They are also used in cooling systems. The EVS Robotics system helps make these exchangers for many jobs.